- Russian Dam Disaster: Assessing the Cost of Failed Safety Practices

- Analyzing the Human Element of the Russia Dam Disaster

- Turbine 2: How a Track Record of Uncertainty Led to Disaster

- Russian Dam Disaster: A Reckoning for Bypassed Safety

- When Running People Past Their Breaking Point Effects Safety: The Bayer Crop Science Incid…

INCIDENT

Mechanical Failures and Misunderstandings

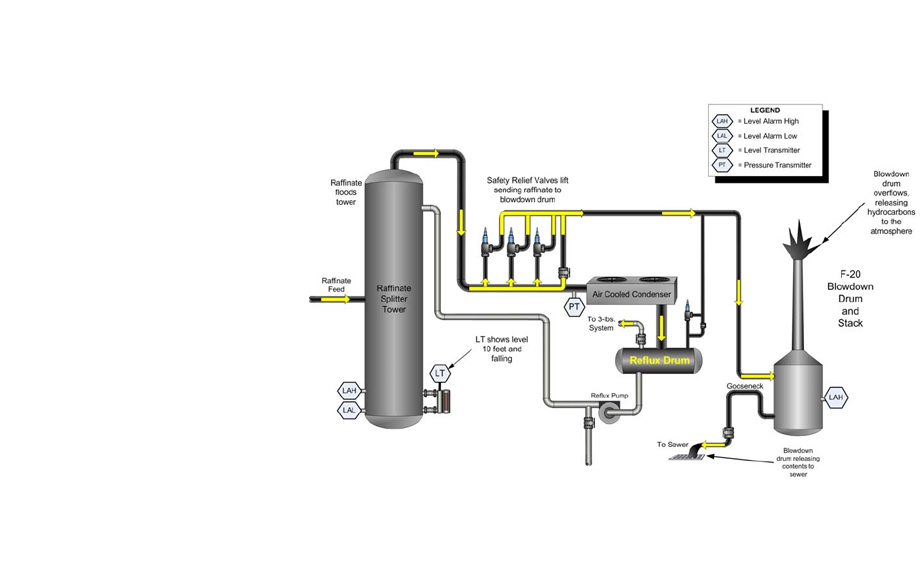

On March 23, 2005, the raffinate splitter process was being restarted after a turndown. The unit had been shut down February 21 so that the tower could be drained, purged, and steam cleaned to remove residues.

Apparently nothing had been done to check level sensors installed in the tower, and a sight glass mounted at the bottom that had been too dirty to use for some years was untouched. Operators preparing for the restart had reported that a pressure vent valve on the reflux drum could not be operated from the control room, but this was not fixed either.

According to BP procedures, that single valve malfunction alone should have prevented restarting the unit until it could be resolved.

While Layers of Protection should remain functionally independent from each other, it’s also important streamline the management of process safety.